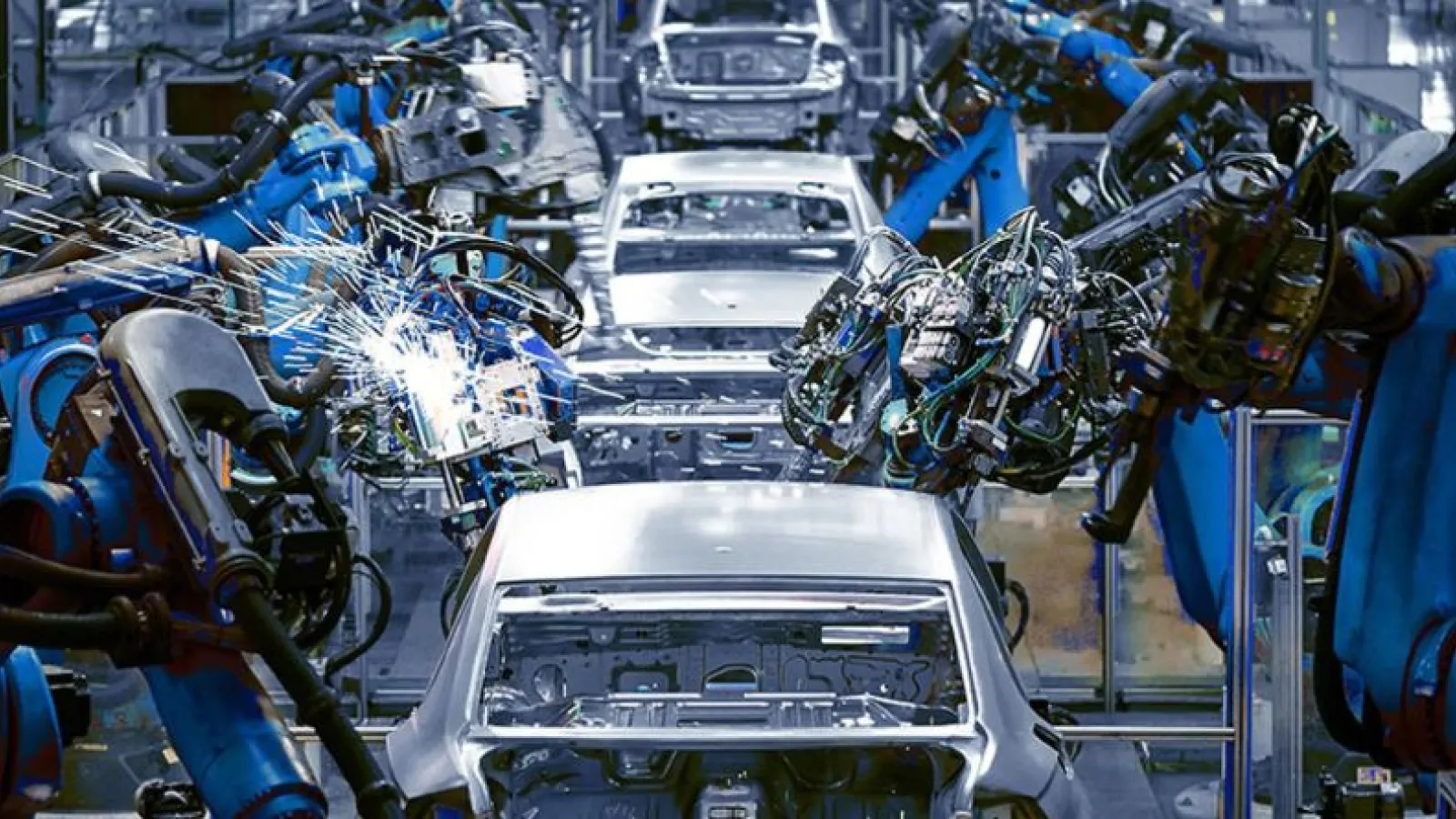

Manufacturing

Our tracking solutions help manufacturing businesses stay competitive by improving key processes from production to quality control through to warehousing and distribution.

Key Benefits

Optimize your manufacturing business with tracking technologies

Our integrated tracking systems deliver valuable information on the location of your assets, support compliance with quality procedures and the deliver vital information for strategic business decisions such as which assets to invest in and where any operational bottlenecks occur.

Are you meeting your production goals?

In a climate of growing competition and shrinking margins, many manufacturing businesses rely on lean manufacturing processes. To lower the cost of stock holding, more and more companies are looking to increase inventory accuracy and reduce excess stock to free up capital. In addition, manufacturers face costly disruptions to their production processes if critical parts, assets or tools cannot be located.

Using the latest tracking technologies such as RFID, BLE, UWB, LoRA, GPS and more we can help support lean manufacturing by capturing accurate, real-time information about your inventory and assets. Tracking the locations of critical assets or even people gives visibility of their locations and eliminates any bottlenecks in production.

Improving supply chain management

Our solutions are helping many businesses improve production output by streamlining supply chain processes. This includes production flexibility, consistent delivery and order fulfilment, warranty and returns processing as well as inventory and asset management. Tracking your assets and inventory can provide:

- Kanban processes for fast replenishment

- Truckload audits to match ERP/WMS with actual shipment

- Location visibility of assets, products or parts in the supply chain

- Accurate inventory levels in warehouses and yards

Work in progress (WIP) tracking

In the manufacturing industry ‘work-in-progress’ tracking is vital to ensure production processes can happen efficiently and without delay.

Our WIP tracking solutions provide management and operational teams with real-time information on production processes to deliver:

- Enhanced product quality through product tracking

- Increased efficiency

- Valuable data to improve strategic business decisions

- Reduced need for excess stock with better inventory management

Worker automation and task management

To improve productivity, companies need to increase staff efficiency. Our software platform can help empower your workers with real-time information and tools to be more efficient.

This can include Kanban processes for fast replenishment and smart stock holding, forklift route optimization in warehouses or on the production floor as well as employee task tracking and KPI reporting.

Our manufacturing tracking solutions include:

Warehouse real-time inventory tracking

Worker productivity tracking

Tracking returnable transport items (RTIs)

Yard and outdoor storage management

Asset tracking