Case Study: Addenbrookes Hospital

Medical device management with GS1 compliant RFID labels

With its 1000 beds and 61 wards, Cambridge University Hospitals NHS Trust (CUH), encorporating Addenbrookes Hospital, is one of the largest and best known hospitals in the UK. The Trust provides high-quality healthcare for the local people of Cambridge, together with specialist services for a regional, national and international population.

Overview

By pioneering the use of active and passive RFID technology, and implementing GS1 standards to manage mobile medical equipment, CUH has improved efficiency, increased patient safety and reduced capital expenditure.

In 2015 CUH became the first NHS trust in the UK to introduce GS1 standards for tracking medical devices. To ensure that they could fully benefit from fast data capture and location data for inventory management, CUH chose a passive RFiD Discovery system to support their GS1 implementation.

The implementation

When choosing to implement GS1 compliant labelling, the Trust had already experienced huge benefits from tracking 7,500 mobile devices with an active RFiD Discovery system for a number of years. In order to enable CUH’s wards, departments and Clinical Engineering team to track the locations of all of their medical assets, the remaining assets have now been fitted with passive RFID asset tags which are fully compliant with GS1 standards.

The project to roll out GS1 compliant new asset labelling utilising passive RFID technology started in May 2015 and was completed in October 2016. To date a total of 37,500 units have been tagged with either or both active and passive RFID tags.

How does it work?

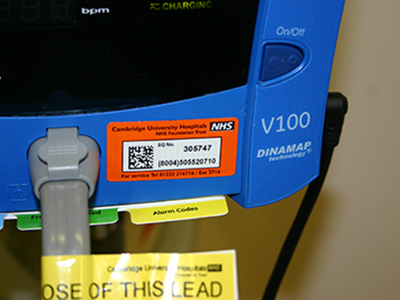

Passive RFID labels replace the existing asset labels, and are fully compliant with GS1 standards, carrying a Global Individual Asset Identifier (GIAI). They are encoded with a unique ID which is linked to a particular asset in the database on registration. Unlike active tags, passive RFID tags have no battery and require an external source to trigger a signal transmission such as a passive RFID reader.

CUH’s Clinical Engineering staff use two different types of passive RFID readers, which capture data from the tags and send location information to a central database. A specially designed trolley fitted with a UHF RFID reader and three antennas performs equipment searches as it is pushed around the hospital recording the date, time and location.

Professor Paul White, Head of Clinical Engineering at CUH, explains:

“This integration allows our clinical engineering and clinical teams to see the location of any medical device assets fitted with an active RFID tag and – as GS1 labelling progressed – the location of those fitted with the new passive asset labels.”

Key Benefits

• GS1 Compliance

• Rapid auditing

• Improved inventory management

• Reduced capital expenditure

• Helps achieve and maintain compliance including

• CQC and MHRA

Challenges

One of the challenges prior to implementation of GS1 asset labelling was to choose the best suitable RFID inlay type to ensure that label sizes were appropriate for application to all different types of medical devices.

Professor Paul White explains:

“We worked closely with the RFiD Discovery team to ensure label sizes would be suitable for all different types of medical device. We also successfully carried out a number of due diligence tests to establish the best position for labels to be applied on each type of device.”

The correct positioning is crucial to ensure that the asset tag does not interfere with the regular use of the device but at the same time guarantees a successful signal transmission to allow for the device to be captured by a reader.

“Using RFID technology has improved our care and provided a phenomenal return on investment by saving us hundreds of thousands of pounds and thousands of hours of nurses’ time.”

Professor Paul White, Head of Clinical Engineering

Benefits

GS1 and Scan4Safety

Improved inventory management

Improved risk management

Reducing capital expenditure for new medical devices

By improving utilisation levels for existing equipment e. g. tagging all ECG monitors, helped improve the use of existing devices resulting in a lifetime capital cost saving of £175,000. The one-off cost of tagging all ECG monitors was just £16,000.

Allowing the Clinical Engineering team to focus on core tasks

By locating equipment faster, the Clinical Engineering team can focus on core tasks of maintenance, repair and delivery of medical devices to the wards.

Reducing time spent on searching for devices

Ensuring clinical staff spent less time searching for devices allowing more time to support patient care

Reducing audit time

Reducing the time it takes to audit the average ward from 1 hour 30 minutes to just 8 minutes. This enables more effective use of engineers’ time and allows for more frequent auditing.

Improving the management of hired devices

For example, a first year saving of £99,441 on rental costs has been achieved by tracking hired low level beds to enable a timely return as well as avoiding necessary replacement costs of hired beds that had been lost.

Plans for the future

RFID asset tracking is already being used for many other types of asset across the whole of the Trust such as moving and handling, wheel chairs, tablets and communication aids. Its use will be expanded further to include areas such as IT (computers, laptops, tablets) and estates (TVs, microwaves).

For CUH the next stage in the process of moving towards GS1 compliance is to introduce Global Location Numbers (GLNs) to identify each location within the hospital and use of the system for other departments and sections within the Trust as part of the wider GS1 implementation.

“RFiD Discovery is the backbone of our medical equipment library – it gives us data which provides vital information for decision makers at the Trust. Over the years using RFID technology has improved our care and provided a phenomenal return on investment by saving us hundreds of thousands of pounds.”

Professor Paul White, Head of Clinical Engineering